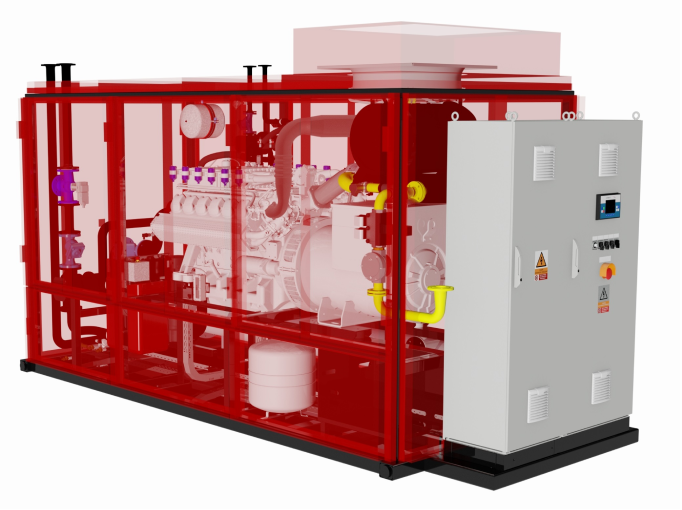

KN Series

CHP Model #

Natural Gas RicH-Burn CHP Modules

The simple solution for lowest emissions and steady performance. KN Series Natural Gas CHP modules harness the reliability of naturally aspirated rich-burn engines with on-board 3-way dry exhaust catalyst to meet the most stringent air permitting requirements while providing superior electrical load acceptance and transient stability in island mode/grid outage operation. Chose from 4 models or build your lineup with multiple units in parallel.